Quality Under Control: Every Batch of Fuel is Checked in Our Own Testing Laboratory

When we claim to be selling only high-quality fuel, we are 100% sure of this, because we take a sample from every batch of petroleum products that arrive from a manufacturing plant in Europe, America, or the Middle East, which is then analyzed in our own quality control laboratory. And only having made sure that the fuel complies with the state standards of Ukraine, do we release it for sale.

Our laboratory has been accredited in accordance with the international ISO170-25 standard, and the company’s investment in its creation is still considered to be one of the most important. Equipment, premises, maintenance of technical records — everything here meets the requirements of the international standard. Of course, the accuracy of research also depends on the person. Our specialists are also accredited, they study and improve their competence on a regular basis.

In fact, quality consists of many parameters, and the main task of laboratory employees is to control each of them. Thus, diesel fuel must meet at least 19 indicators, gasoline – 15, and LPG – 10.

First, the selected test sample is entered into a special register, and then a full cycle takes place: from analysis to a 45-day storage.

Why should the fuel be stored in the laboratory for so long? These samples are also called “arbitration samples”, and their storage is another requirement of the DSTU. This is done in case of possible disputes. That is, if a consumer has doubts concerning the fuel quality, this sample is forwarded to an independent laboratory, which renders the final verdict.

Quality verification is not a moment’s work. Gasoline test takes the longest time. On average, specialists spend about 7 hours analyzing one sample. It takes up to 4 hours for diesel fuel, and the least amount of time is required for LPG, i.e. about 3.5 hours. However, if required, they also carry out express analysis.

Dozens of studies are conducted within a month. This summer, for example, more than 40 samples of LPG were checked for compliance in just one month. It’s meticulous work, but it’s the only way for us to make sure we are offering you the best.

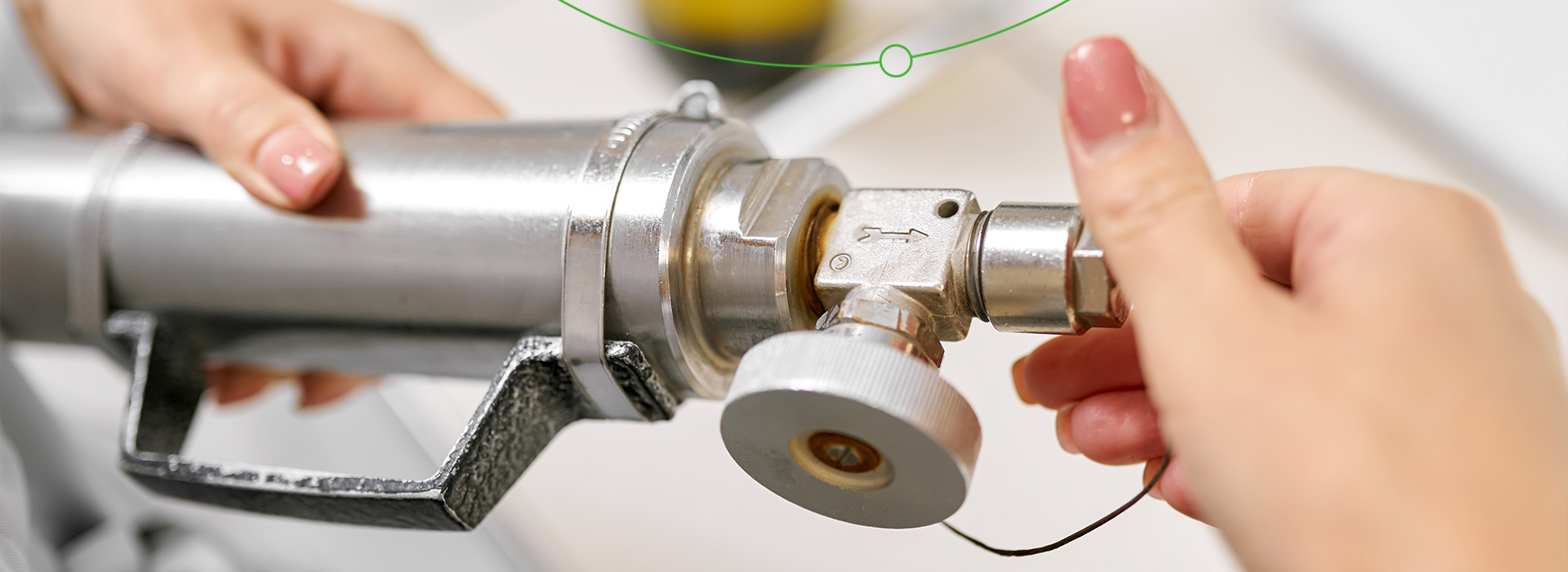

To ensure the fuel will meet the manufacturer’s stated parameters by the time the drivers fill their car tanks with it, we apply a multi-stage control system. We take notice of everything: analyze samples from each batch, control the protective seals of fuel trucks, and constantly clean fuel tanks at oil depots and gas stations. We monitor every link in the fuel logistics chain.

So, when we claim that the quality of our oil products is at the highest level, it is the mere truth. And we are responsible for it with our own name.

Thank you for choosing UPG!